How DO we measure so many skis?

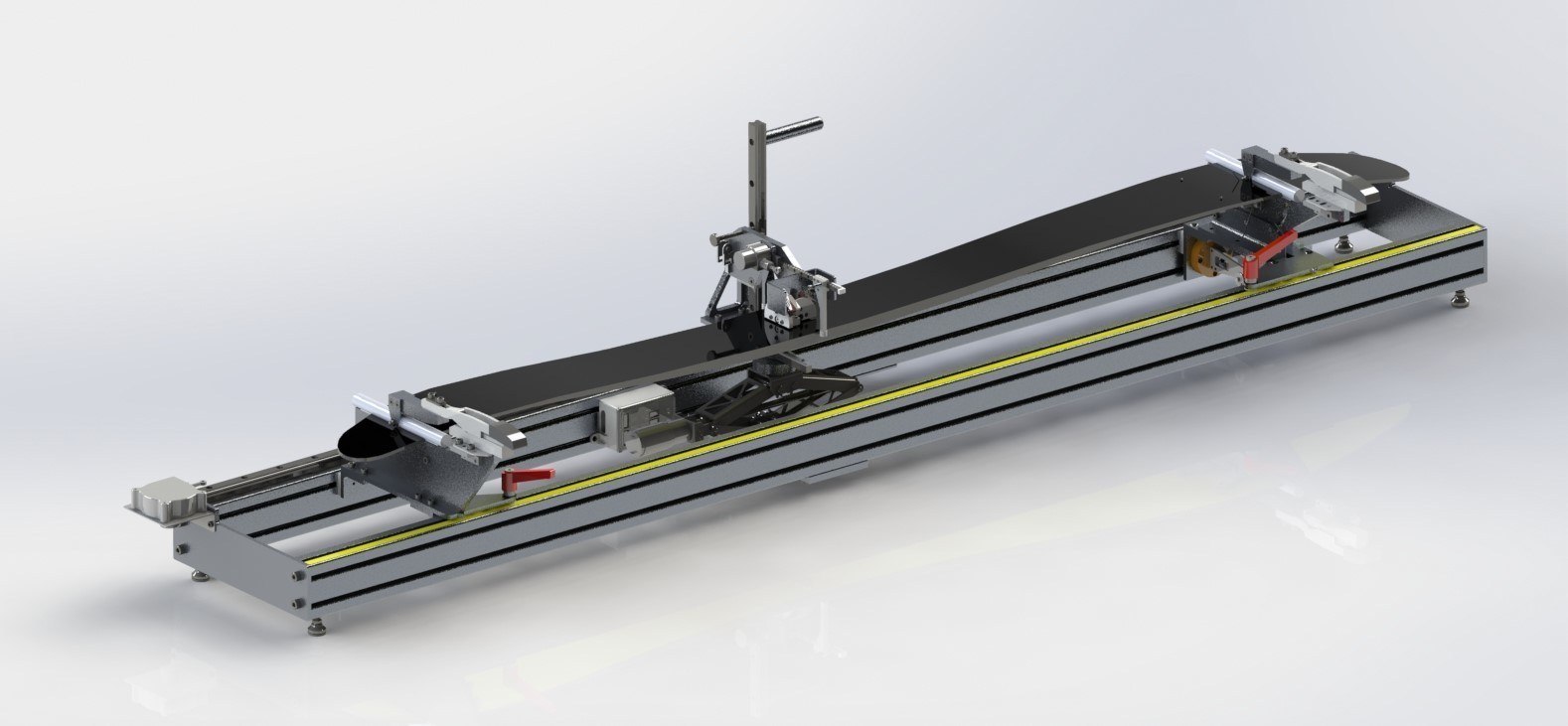

We have developed a patented technology specialized for measuring skis

It takes UNDER 2 MINUTES to obtain precise measurements of the full width and height profiles (sidecut, taper, camber, tip, tail and rockers), as well as the ski bending stiffness distribution, the ski torsional stiffness distribution and the ski weight. Our measuring system has superior accuracy to laser technology.

WHAT DO WE MEASURE?

Our measuring technology collects raw data

A typical data file for one ski includes 10,000 values to describe the following:

- Geometry - Width along the entire ski

- Profile - Tip, tail, rocker and camber along the entire ski

- Ski bending stiffness - Distribution along the entire ski

- Ski torsional stiffness - Distribution along the entire ski

- Ski weight (center of mass and inertia are also possible)

The bending stiffness of a ski, also known as the flex of a ski, is its resistance to bending with applied loads. The torsional stiffness of a ski (aka torsional flex of a ski) is its resistance to twisting loads. Stiffness is also often called rigidity and is the ratio of the resulting displacement to the applied force.

From raw data, we calculate precisely any value you may want to use. Here's a list of typically extracted values added to our database for each ski we measure:

Dimensions

Measured Length (cm)

Running Length (cm)

Sidecut Length (cm)

Effective edge (cm)

Tip (mm)

Waist (mm)

Tail (mm)

Sidecut Radius (m)

Mass and Float

Mass (g)

Surface Area (cm²)

Split Surface Area (cm²) - Front, Rear

Surface-to-weight Ratio (cm²/g)

Rockers

Tip and Tail Height (mm)

Tip and Tail Length (mm)

Front and Rear Rocker Length (mm)

Shapes

Tip and Tail Taper Length (mm)

Front Contact Point Range (mm)

Camber (mm)

Setback (mm) or mount point

Stiffnesses

Average Bending Stiffness (Nm²)

5-point Bending Stiffness (Nm²) - Tail, Aft, Center, Front, Tip

Average Torsional Stiffness (Nm²)

5-point Torsional Stiffness (Nm²) - Tail, Aft, Center, Front, Tip

Custom calculations

Custom calculated values are simple to extract to match any measures taken manually (such as QA/QC checks)

Any specific stiffness test with conversion to loading, displacement... (such as 3-point or 5-point bending stiffness test)

HOW GOOD ARE THE MEASUREMENTS?

Our technology beats any competing measuring system

Precise Measurements

- 1 mm longitudinal resolution measurements

- 0.1 mm precision on width measurements

- Span up to 5 cm from tip and tail ends on geometry

- Higher accuracy than laser technology

Ski Bending & Twist

- Unique ability to measure the bending and torsional stiffness distributions of skis

- Designed to measure 99% of available alpine skis

- 5% relative accuracy

- 10 cm spatial resolution (averaging segments) ; allows

detection of localized variations

Fast & Easy

- Under 2 minutes to perform a complete set of measurements

- Use SKU numbers for quick product identification

- Data immediately available in CSV format

- Integrates with company design database and calculates internal KPI from measured values

- Minimal operator training required

Patented Technology

- Unique patented measuring technology

- United-States patent #1111889 "METHOD AND APPARATUS FOR MEASURING RIGIDITY DISTRIBUTION"

Why Measure ski properties?

Measuring more reduces costs and time to design, while increasing precision and quality

- Evaluate the impacts of a design change or iterations in a matter of seconds

- Drastically reduce cost related to on-snow testings and tester comment compilations

- Speed up the development of complete lines of models based on measurable key metrics

- Calibrate computer-aided models (company design templates)

- Compare target profile to produced profiles

- Match pairs of skis from different attributes

- Execute quick and accurate quality controls on mass production output compared to original design specifications

- Communicate efficiently with distributed teams

- Provide detailed specifications for manufacturing contracts and ensure raw material variations are taken into account in the manufacturing process

Measured data representation possibilities

DPS Wailer 184 (2015)

Complete geometry, bending stiffness and torsional stiffness profiles

Graph 1 - Shows the profile of the ski and weight | Graph 2 - Shows the geometry (measured) and edge contact (full line being the effective edge and dotted lines continues up to the maximum width of the ski) | Graph 3 - Shows the ski bending stiffness distribution profile (EI) and average EI | Graph 4 - Shows the ski torsional distribution profile (GJ) and the average GJ. ALL MEASUREMENTS WERE TAKEN IN LESS THAN 2 MIN.

Rossignol 2017

WC9GS Ti vs Hero ST Ti vs Hero ST C

Bending stiffness and torsional stiffness profiles comparisons

Measure ski properties to compare designs without testing them on snow. In the case above, we can observe Rossignol Hero Ti version has about 50% more torsional stiffness compared to the Rossignol Hero C version, while both skis' bending stiffness are the same. Furthermore, the Rossignol WC9GS is significantly stiffer in both bending and torsional stiffness.

Atomic 2017

Backland 164 vs 173 vs 182

Bending stiffness and torsional stiffness profiles comparisons

Measure ski properties to determine the ideal variations for each length. No need to test on snow. Ratios of target variations are way more precise and easier to measure with our measuring technology. In the representation above, we can clearly see the evenly distributed bending stiffness increase, while the torsional stiffness increase is unevenly increased.

Quotes & details

Please contact us to get more information including a detailed quote with complete technical specs.

HOW IS THE MEASURING DONE?

Designers, product managers...

Subscribe to our newsletter to follow our product development.

By subscribing, you accept our privacy policy that can be consulted at anytime here.

Who is already Using our technology?

Major brands, new brands, smaller brands... have incorporated the use of our measuring technology for designing, classifying and manufacturing QA/QC

Stockli has been developping their race line of products as well as their regular products with a race version of our measuring machine. This version enables them to measure any ski up to 230cm length.

Atomic has been developping their race line of products as well as their regular products with a race version of our measuring machine. This version enables them to measure any ski up to 230cm length.

Salomon has been developping their race line of products as well as their regular products with a race version of our measuring machine. This version enables them to measure any ski up to 230cm length.

WNDR Alpine is using biotechnology to design materials derived from microalgae specifically for backcountry skiing. The resulting skis are measured with our technology to ensure properties match skiers' expectations. Measuring also saves money in the design steps by speeding up the process from lab to manufacturing.

Rossignol group has been using our technology for their race division designs. Measuring ski bending and torsional stiffness is a key aspect to creating the ideal race equipment. The ability to precisely measure each modification within 2 minutes saves a lot of time in the rigorous design process. More recently, our technology has been used for the development of all other type of skis.

Ferreol is a brand specialized in high performance skis 100% designed and manufactured in Quebec, Canada. They strive to build eco-friendly skis with alternative materials such as hemp. They use our technology to evaluate alternative materials and layups in their designs.

4FRNT has been using our technology to measure certain models preferred by their pro riders and to create very precise manufacturing specifications. This ensures compliance from white room to manufacturer, including testing by pro athletes.

Canadian company Genuine Guide Gear develops skis and related equipment focused on backcountry skiing and snowboarding culture. They have been using our technology since 2017.

K2 skis is among the worlds largest ski manufacturers. They have an advanced test center to measure ski properties and have been using our technology to develop and fine tune their alpine skis.

Original+ is an Austrian ski manufacturer that specializes into custom skis. They use a unique digital ski configurator to help determine what would suit you best. They have been using our measuring technology since 2022 to build their products.

Canadian hockey equipment manufacturer Bauer produces hockey sticks for every level up to NHL players. They have been using our technology since 2017.